Sensorless or Sensored ?

You might have heard the terms "Sensored" and "Sensorless" automation. Both words are formed by the same root "Sensor", which in our market is also commonly called encoder. Hence, a “Sensored” automation represents an automation with an encoder. On the other hand, a “Sensorless” automation is an automation without an encoder.

Encoders differ in type and resolution. An encoder can be optical or magnetic and its resolution is measured in PPR (Pulse Per Revolution), higher the value implies more resolution. The primary function of an encoder is to understand how many rotations a shaft on which it has been positioned has completed. For example, consider an encoder emitted 48 pulses (P) and its resolution is 8 PPR (PPR). With this data we can calculate how many complete rotations the shaft has made (SR):

SR = P ⁄ PPR ovvero SR = 48⁄8 = 6

PTo obtain this result, the resolution of the encoder is of little importance, an encoder with 2 PPR would perform the same function yielding the same result (P = 12; PPR = 2 therefore SR = 12/2 = 6).

Optical encoders are among the most used and common in our sector and generally have a low resolution, around 8 PPR.

Magnetic encoders, on the other hand, range from low resolutions, 2 PPR, to very high resolutions, over 4000 PPR.

Gate automations with 220V technology, would not benefit from higher resolution because it would not entail a substantial increase in performance. This is due to a physical limit of the 220V technology itself.

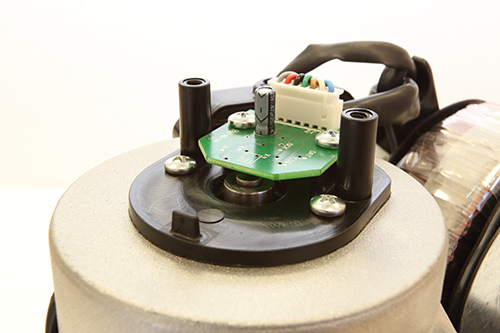

While, in digital motor solutions, resolution is important and as it increases, control and safety increase as well, so much so that Roger Technology uses 4096 PPR magnetic encoders in its "sensored" brushless solutions.

This resolution allows the "sensored" brushless automations to have control over the rotor up to the tenth of a degree (0.1 °), thus making the automation impeccable in obstacle detection and ready in case of emergency maneuvers. In addition, it guarantees fluidity and precision in accelerations and slowdowns, characteristics that the hearing enjoys, and the sight appreciates.

But if encoders are so important how can a motor be “sensorless”?

The answer lies in the brushless digital motor technology. A brushless digital motor is in fact a huge encoder, which can be analyzed by a powerful processor that extrapolates the position of the rotor during its motion without the aid of an external encoder. This is also the reason why the "sensorless" brushless motor is defined with the term "native encoder", because the brushless motor is its own encoder. It is also for this specific reason that the “sensorless” version of our solutions is only available with our brushless digital motor.

Our brushless motors as encoders offer a 48 PPR resolution which is higher than most popular encoders available in our market, thus we can ensure movement fluidity, safety and readiness in case of emergency even without an encoder.

this page |

Nederland

Nederland Italiano

Italiano Français

Français Deutsch

Deutsch Belgium

Belgium Português

Português Español

Español Polski

Polski